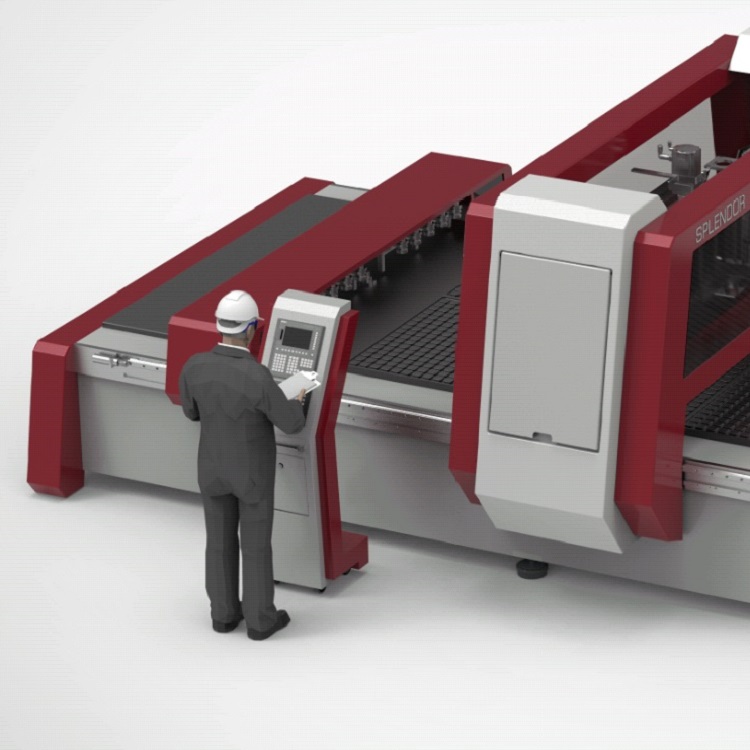

SIMAKSAN CNC Woodworking Centers.

SIMAKSAN CNC Woodworking Centers offer solutions for woodworking and furniture production thanks to their superior technical properties.

In addition to standard production, we offer options in the direction of our clients' requests. The most important feature of our machines is the ability to work at high speed with high speed. Monobloc steel bottom plate body and bridge structure tested under the most severe conditions.

SIMAKSAN CNC Woodworking Centers equipped with reliable equipment guarantee trouble-free operation.

Models and Technical Specifications

SIMAKSAN CNC Machining Centers, which are produced as standard two models, also offer special production possibility depending on the possibilities of completely customer request and technology.

SIMAKSAN CNC Woodworking Centers, Mdf, Chipboard, Wood products and so on. as well as lightweight materials such as wood.

The bench is suitable for standard cutting and 3-D surface finishing operations.

With fast and precise cutting processing capabilities, you can achieve the ideal production capacity.

CNC CONTROL SYSTEMS

Machine operating system use SIEMENS SINUMERIK 808D ADVANCED as standard.

- 7.5” color LCD display

The SINUMERIK 808D ADVANCED control is a panel-based CNC for the basic performance range. This compact and user-friendly entry-level solution is used for basic woodworking applications.

For simple milling functions, based on its hardware and software expansions, SINUMERIK 808D ADVANCED offers sufficient performance for woodworking.

ELECTROSPINDLES

As standard SPINTECH uses domestic spindle. It provides excellent results in milling applications including 3 dimensional machining. The spindle can be selected according to the customer's request.

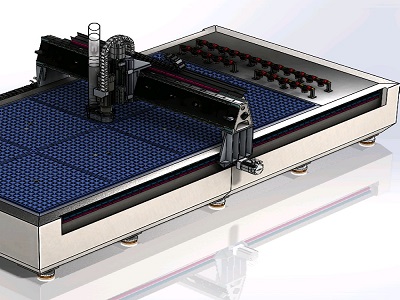

MAIN FRAME and BODY

The machine table is manufactured as a modular steel construction, as a bridge monoblock steel body. The machine axes are equipped with gear racks and pinion gears for precise positioning and rapid movement.

TOOL CHANGE SET-UP

Reduction of tool change set-up time and the possibility of operator error, thanks to the contact pre-setter, which automatically determines the length of the tool.

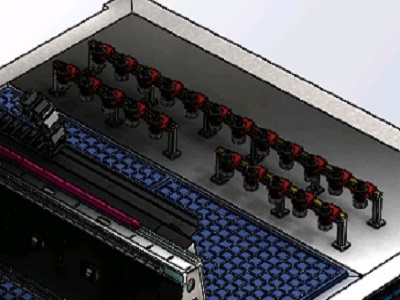

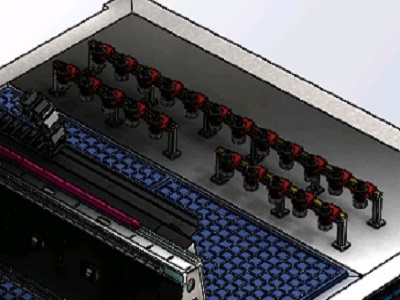

TOOLS MAGAZINE

The pick-up changer for 12 tools is integrated into the machine frame and protected against dust and chips by a pneumatically controlled cover. An upgrade option is available for up to + 12 tool stations.

NESTING TABLE

Universal work table with a solid structure to machine panels with the maximum reliability.

REMOTE CONTROL

The Remote control allowing the operator immediate, direct control.