NC BACK SPOTFACE MACHINE.

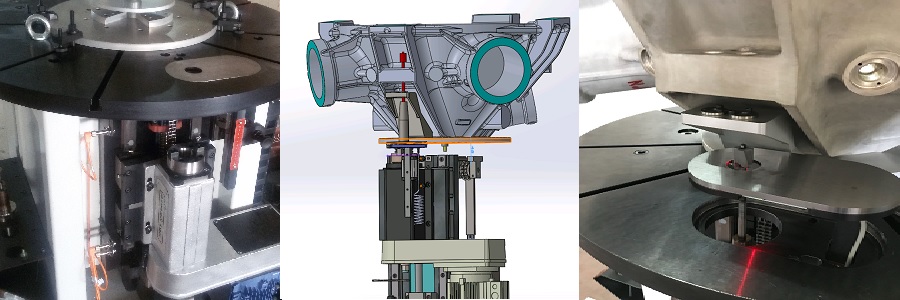

SIMAKSAN CNC Back Spot Facing Machine is designed and manufactured to provide the requirements of especially the aerospace industry.

The machine enables processing of aluminum, magnesium alloys and composite workpieces within tolerance.

Beside the standard production, we offer options according to the demands of our customers.

The most important feature of our machine is the ensure to work at high standard with different sizes of tools.

Monoblock Body and steel table, Servo Motor group structure tested in the most severe conditions.

SİMAKSAN NC Spot Face Machining Centers with reliable equipment guarantee trouble-free operation.

TECHNICAL SPECIFICATIONS

| TABLE SIZE | Ø 37" - 940 mm |

| "Z" TRAVEL | 300 mm |

| SPINDLE POWER | 1.5 kW |

| SPINDLE SPEED | 150 - 750 rpm |

| TOOLS MAGAZINE | 6 Tools Manuel |

| MAIN POWER | 3.5 kW |

| WEIGHT (a.) | 1300 Kg |

| WORKING AREA (a.) | E:2000 x B:1600 x h:1500 mm |

NC Spot Facing Machines are completely produced by SİMAKSAN according to customer requirements.

SİMAKSAN NC Spot Facing Machine has been developed to process light materials and composite materials such as Magnesium and Aluminum alloy. The bench is suitable for standard spot (backlight) and back spot face. It enables you to reach the ideal production capacity with fast and precise cutting machining capabilities.

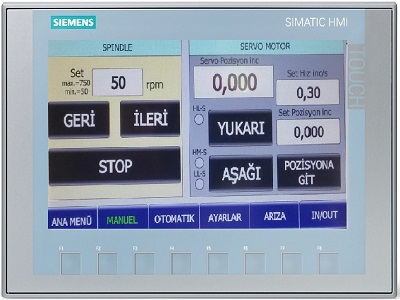

NC CONTROL SYSTEMS

The Machine Control System has a touch control panel for the SIEMENS SIMATIC HMI (Human Machine Interface).

CUTTING TOOL SELECTION and PROGRAMMING

Spot Face machining tools provided by Users are managed from the Control Panel and allow for quick operation rotation.